SHARPENING

PLANES AND

CHISELS

Jerry Nelson, Dec 2004

Jerry Nelson, Dec 2004

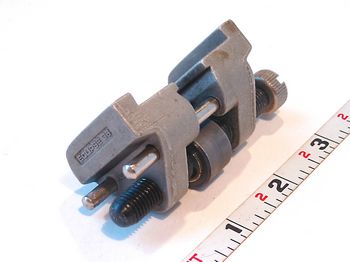

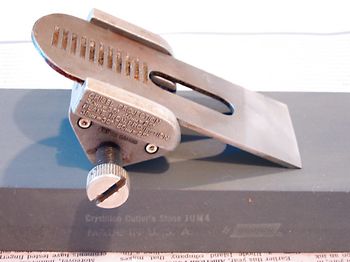

A honing guide like this "Eclipse" from England is a great way for woodworkers to learn to sharpen chisels and cutting irons from wood planes ("plane irons"; see photos below). It's sold as something to use forever, but don't be fooled. You want to learn to do this freehand. These are the kiddie learning wheels that got many of us started. Please read on if you are a beginning or aspiring woodworker. Sharp tools are a pleasure and you should have the best. (Woodcraft sells this honing guide, or search on "honing guide"; Google has a catalogs engine where you'll find competing brands, some cheaper.)

click any photo to enlarge

MY TWO BITS ON SHARPENING PLANES AND CHISELS

I used this honing guide like "helper wheels" on my first bicycle. It helped me learn to walk up to a bench stone and sharpen anything freehand and fast. I am saying goodbye and passing on what I learned so you can try. Just start pushing yourself gently to a higher skill level. You can't force a motor skill. But if you do nothing for a year, you'll pick up at a higher level of skill each time you resume. Just start.

Read up on the proper "stance", clear the bench off, make yourself comfortable. You want to use both hands to run the tool over the stone in a figure-eight pattern. You must do this push-and-pulling without causing the cutting edge of the tool to tilt away from perfect, flat contact with the stone--even a split second. (laughter) By "freezing" your upper body that holds the tool, and rocking back and forth on your feet (spread somewhat wide apart on the floor for stability), you can minimize all the poorly-controlled arm and hand motions that would likely skew the blade out of perfect, undisturbed contact. I assume you can easily find out everything you should do. The problem is, you can't do it.

Use this Eclipse guide to get started on the coarse stone(s).

IMPORTANT HINTS nobody ever tells you:

(1) start practicing freehand on the finest stones -- the smoothness of the ride will magnify your "feel" for perfect positioning and contact, whereas the rough ride on a coarse stone throws you off. Observation: Fine stones need finer lubricants. From fine to coarse, useful lubricants are water, water with liquid detergent, kerosene, fine oil, heavier oil. If you use oil that is too fine, it can't hold the larger particles that a coarse stone casts off, and won't make a good grinding slurry. Mineral oil from drugstores smells nicer than what they sell in car stores.

Hint #2: use a lubricant that is a little too heavy for the stone you are learning on. If you use heavy oil and a glass plate, the blade will still be stuck in perfect position after you take your hands off it (OK, I'm exaggerating, but you get the idea). If you overdo it, the lubricant will do such a good job of protecting the metal, you won't grind anything off it -- great for car engines, but not the idea here. Thicken up the lube to learn, but not so much that you don't cut.

Note: the cutting edge is a long rectangular patch of metal, and usually you orient that patch ACROSS the bench stone, then try to shove the blade all the way down the long stone without changing its tilt (laughter).

Hint #3: the more you rotate the blade to "point" in the direction of back-and-forth travel, and away from just straight across the stone, the easier it becomes to avoid unwanted tilts. A diagonal angle kind of braces the blade against tilts in either direction.

Read everything on honing, believe only what you want to. Don't get into any religious arguments -- this is your private journey, and you can change the stone, the lubricant and your "body English" any way you want to.

You will make mistakes (OK, OK, **I** made mistakes, but you live in a parallel universe, and it won't happen to you). The more you screw up the blade by rocking out of the right grip and rounding over the edge, the more impossible it becomes to feel the blade "click" into alignment with the stone's surface and recover. So clamp it in the Eclipse, get it perfectly flat again on a coarse stone, and return (maybe another day, that's OK) to practicing on a fine, heavily-lubricated one.

WHAT THEY NEVER TELL YOU -- CARE OF BENCH STONES

You can't do the job on one stone. There will always be at least two. If you are going to transfer the cutting iron from one stone to another, then, if the surfaces of the two stones do not perfectly match, you are screwed. The 2nd stone is finer, right? So it cannot change the **shape** of the iron, right? After the coarsest stone, the finer stones -- the whole honing procedure -- is designed to change only the **surface finish**. It can only bring the edge closer to a mirror finish and a razor's precision.

The only shape you can hope to achieve on any stone that will perfectly match all other stones is flat -- perfectly flat. It doesn't matter if you are freehand or using the Eclipse honing guide. It doesn't matter if you started by hollow grinding on a motorized grinding wheel, if your religion premits that. If you are going to put the finishing touches on with bench stones, you need the freedom to use as least two grades of them, and that means the both have to be perfectly flat. It's time to sharpen (ok, flatten) the stones.

So now your hands are covered in blackened oil that would ruin the $400 cherry wood boards if you so much as touched them, you took time off to sharpen your tools and have to tell the family you need to sharpen the stones to sharpen the tools to fix the plane to smooth the boards to begin the glue job that . . . Glad I could be so much help.

HOW TO FLATTEN BENCH STONES

1. Buy three bench stones. It's nice if they are a) big b) coarse and c) identical, but any 3 will do. If the stones really are identical, bevel different edges so you can tell each stone apart. If the stones are el cheapo antiques from eBay, roughly flatten them on the sidewalk in front of the house.

2. Live it up and buy some #220 or #150 grit silicon carbide (or aluminum oxide) abrasive from stone tumbling hobby stores.

3. Sprinkle oil and grit on all the stones.

4. Rub stone A against B, then A against C and B against C.

Think about it: if a stone has corrugations, rubbing it on another stone or the sidewalk will smooth out the bumps, leaving only a simple curve. Maybe the corners are rounded off and the middle is high, or maybe the middle is hollowed out, but it doesn't go up and down all over the surface. Just a simple curvature. If A & B are rubbed against each other, then the curve, whatever it is, becomes equal and opposite in each stone (the stones are "mated"--they get hard to pull apart; you can see what's going on in the reflections off the oil when you slide them apart). If A and its mirror image B are then each rubbed against C, they will average out. The average of equal but opposite curves is no curve -- flatness. Maybe the flatness isn't perfect. So, now "mate" C against A, and average them both out against B. Either keep compulsive track of everything, count your stokes, and rotate the stones' orientations not just their rubbing companions, or have a sherry and use the random approach (if you are confident that you really are a perfect slob and your behavior **is** random, the random approach is fine). Either way, you will get a flat surface that is optically perfect. With a fine stone and a little oil, you will soon see a reflection of your face as clear as any mirror's -- not as bright, but perfectly straight. If you actually enjoyed getting down to fractions of a mill precision--thousandths of an inch--using little more than rocks and newspaper in your basement, the next step is grinding a telescope mirror and getting down to a precision level equal to about 1/4 the wavelength of visible light. At this point, mostly you just need a cleaner basement now that you've ruined this one with too much spilled #150 grit abrasive. That stuff is very hard on ball bearings, not just telescope mirrors. A little in the German engine oil, and you'd get shot in any World War Two movie on the French Resistance I've ever seen.

CONCLUSION

Life begins with a set of stones, not a honing guide, not a plane and chisels, and certainly not a pile of cherry wood. If the "master set" of stones are coarse, man-made silicon carbide stones, they can be used to keep all the littler, finer, softer stones flat also. You only have to do the ABC routine with one set of stones, only once in a while. If all the stones "mate", then, after the coarsest stone, it's 10 - 20 strokes on one or two others and you're done. Hand honing is not tedious. It is very fast. It takes more time to clean those deadly hands so you can touch the wood again than it does to sharpen anything. Go for it. If you succeed, consider tango or skiing lessons -- you can do anything. Conversely, if you can already do that, why not this?

--end