is published !!

The Washington Post

Thursday 20 April 2006

The first "letter to

the editor" I ever got published in my life was in the Washington

Post. I would have liked it to be about politics,

but instead it's about airplanes.

The original article has a great graphic showing how an airplane fuselage is built, and where these parts fit in (or didn't fit in) to put the "skin" onto the airplane.

EXTRACT OF ORIGINAL ARTICLE in case you don't have time to read it all:

...Cindy Wall, a company spokeswoman [for Boeing says,] "Our planes are safe."

The three whistle-blowers, however, contend that Boeing officials knew from their own audits about thousands of parts that did not meet specifications, allowed them to be installed and retaliated against people who raised questions. They say the parts, manufactured from 1994 to 2002, fit the Federal Aviation Administration's definition of "unapproved" because they lack documentation proving that they are airworthy. Moreover, they say, forcing a part into place could shorten its lifespan...

After the whistle-blowers notified federal authorities in 2002, the FAA and the Pentagon looked into their charges. Each said its investigation cleared the airplane parts... The Department of Transportation's inspector general also dismissed the charges.

The Post's review, however, found that the FAA did not assess many of the whistle- blowers' key allegations. FAA inspectors examined only a small number of parts in the plants and did not visit any airplanes to inspect the roughly 200 types of parts questioned by the whistle-blowers.

The Pentagon and Transportation Department, in turn, relied on the FAA's work, documents show.

One reason the FAA chose not to pursue the whistle-blowers' claims, officials said, was that... [t]here has never been a crash caused by such a failure, the agency said.

REACTION ON BLOGS

The reaction from

http://gidblog.blogspot.com/2006/04/profits-before-people.html

(Gideon Starorzewski's blog)

"Oh well, by all means, let's wait until people die before addressing a potential and very serious problem; we don't want to ruffle the feathers of of Boeing's stockholders, do we?"

BOEING HAS VIOLATED NATIONAL SECURITY EXPORT REGULATIONS

and sent a gyroscope guidance chip used in military missiles out of the country.

http://www.dvorak.org/blog/?p=4939

The reaction from:

http://www.dvorak.org/blog/?p=5042 the "Dvorak Uncensored" blog

I hope someone at Boeing kicks some serious QC ass over at AHF Ducommun, or we won’t have a commercial aircraft industry soon. How many such reports do airlines (especially foreign) need to see before they exclusively buy Airbus?

--John C Dvorak

Call me unadventurous, but I would rather not be looking down from above the clouds, knowing I was on a plane respec’ed during assembly with Elmer’s, duct tape or ad hoc holes drilled in ANYTHING related to keeping it in the air. If you can’t trust outsourced, low bid subcontractors working for giant military industrial corporations, who can you trust?

Comment by Ballenger on "Dvorak Uncensored" blog

I used to work on the 737 line at the Boeing plant in Renton, Washington [JIN: where the fuselage sections from Wichita, KS, are put together], and this doesn’t surprise me. Shoddy work is fairly common. Sadly, Boeing is still the best of the bunch. While working on Airbus planes I’ve found structural and casting defects hidden with body filler (Bondo-type material for you car guys). I fly if I have to, but I prefer to take the train.

Comment by Mike on "Dvorak Uncensored" blog

REACTION at McLEAN HIGH SCHOOL, VIRGINIA

Jerry '60: I was a kid living in Europe when de Havilland made its own mistakes with the fuselage skin of the Comet airplanes --- the world's first commercial jetliner. The cold war was closing in, and these airplanes kept falling out of the sky. It was pretty scary, which is why I remembered it. The other famous metal fatigue incident in history involved Liberty cargo shops hastily made to supply the troops abroad during WW II. They fell apart in mid-ocean. The Comet's cracks started at the corner of the windows. The Liberty ship's cracks started at the corner of a cargo hold. Moral: always round off your corners. Anyway, now you know why they always X-ray planes. They all have cracks; someone decides when they should stop flying. Feeling better now?

Pam '59: If you are feeling better, why not relax and watch "No Highway in the Sky", a prescient 1951 movie about planes that crash from metal fatigue. Duke '60: Better yet, read the book the movie was taken from: No Highway (1948) by Nevil Shute [Norway], the guy who wrote On the Beach.

Nancy '60: We wanted the Comet, it was the only jet and so much faster. I do remember the Comets being grounded. We were in Burma at the time getting ready to come home and instead of BOAC's Comet I think we came home either on TWA or Pan Am.

Frank '60: ... there was the Aloha Airlines jet that had a large section of the top of its fuselage blown apart but with only the stewardess lost (wear your seatbelt) ... the cause was metal fatigue due to so many inter-island take-offs and landings. One passenger had noticed an anomalous bulge in the side of the plane before the catastrophic decompression. Maybe you remember the details.

Duke '60: ...and let's not forget the catastrophic fuselage failure at 24, 000 feet near Maui in 1988 of a 737-200 (N73711) flown by Aloha Airlines where a skin crease cracked along lap joints under the forces of pressurization and became a full-blown rupture. A senior flight attendant was sucked out through the hole and vanished; 65 of the 89 passengers were injured -- 8 seriously. [JIN: how nice to know the 737s are being built so much more carefully today . . . ]

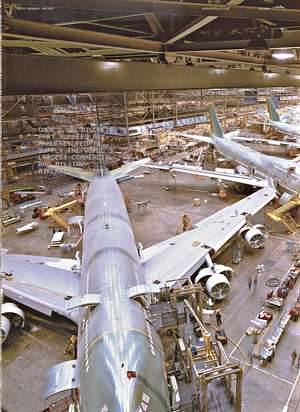

Boeing 737

airframes being assembled from sections built in Wichita Falls, KS.

Photo by Dave Williams, The Wichita Eagle

Photo by Dave Williams, The Wichita Eagle

LETTER TO THE

EDITOR:

The April 17 front-page story "Boeing Parts & Rules Bent, Whistle-Blowers

Say" reported that 737 airliners are getting fuselage skin made from parts

of the wrong size and shape and with pre-drilled holes in the wrong

place; workers drill new holes by hand to put the plane together. The story

said that the Federal Aviation Administration (FAA) did not pursue three

whistle-blowers' tips because the parts in question would not present a

safety risk even if they failed in flight. Such failures have never caused

a crash, the FAA said.

The April 17 front-page story "Boeing Parts & Rules Bent, Whistle-Blowers

Say" reported that 737 airliners are getting fuselage skin made from parts

of the wrong size and shape and with pre-drilled holes in the wrong

place; workers drill new holes by hand to put the plane together. The story

said that the Federal Aviation Administration (FAA) did not pursue three

whistle-blowers' tips because the parts in question would not present a

safety risk even if they failed in flight. Such failures have never caused

a crash, the FAA said.

But in 1953 and 1954 three de

Havilland Comets flown by Britain's BOAC

exploded in midair when their fuselage skins failed, and 99 people died.

With those failures, Britain lost its chance to be the dominant jetliner

supplier for the rest of the 20th century. Britain eventually lost its

business to a rival named Boeing but first it lost its reputation.

JERRY NELSON

McLean

exploded in midair when their fuselage skins failed, and 99 people died.

With those failures, Britain lost its chance to be the dominant jetliner

supplier for the rest of the 20th century. Britain eventually lost its

business to a rival named Boeing but first it lost its reputation.

JERRY NELSON

McLean

The original article has a great graphic showing how an airplane fuselage is built, and where these parts fit in (or didn't fit in) to put the "skin" onto the airplane.

EXTRACT OF ORIGINAL ARTICLE in case you don't have time to read it all:

...Cindy Wall, a company spokeswoman [for Boeing says,] "Our planes are safe."

The three whistle-blowers, however, contend that Boeing officials knew from their own audits about thousands of parts that did not meet specifications, allowed them to be installed and retaliated against people who raised questions. They say the parts, manufactured from 1994 to 2002, fit the Federal Aviation Administration's definition of "unapproved" because they lack documentation proving that they are airworthy. Moreover, they say, forcing a part into place could shorten its lifespan...

After the whistle-blowers notified federal authorities in 2002, the FAA and the Pentagon looked into their charges. Each said its investigation cleared the airplane parts... The Department of Transportation's inspector general also dismissed the charges.

The Post's review, however, found that the FAA did not assess many of the whistle- blowers' key allegations. FAA inspectors examined only a small number of parts in the plants and did not visit any airplanes to inspect the roughly 200 types of parts questioned by the whistle-blowers.

The Pentagon and Transportation Department, in turn, relied on the FAA's work, documents show.

One reason the FAA chose not to pursue the whistle-blowers' claims, officials said, was that... [t]here has never been a crash caused by such a failure, the agency said.

REACTION ON BLOGS

The reaction from

http://gidblog.blogspot.com/2006/04/profits-before-people.html

(Gideon Starorzewski's blog)

"Oh well, by all means, let's wait until people die before addressing a potential and very serious problem; we don't want to ruffle the feathers of of Boeing's stockholders, do we?"

BOEING HAS VIOLATED NATIONAL SECURITY EXPORT REGULATIONS

and sent a gyroscope guidance chip used in military missiles out of the country.

http://www.dvorak.org/blog/?p=4939

The reaction from:

http://www.dvorak.org/blog/?p=5042 the "Dvorak Uncensored" blog

I hope someone at Boeing kicks some serious QC ass over at AHF Ducommun, or we won’t have a commercial aircraft industry soon. How many such reports do airlines (especially foreign) need to see before they exclusively buy Airbus?

--John C Dvorak

Call me unadventurous, but I would rather not be looking down from above the clouds, knowing I was on a plane respec’ed during assembly with Elmer’s, duct tape or ad hoc holes drilled in ANYTHING related to keeping it in the air. If you can’t trust outsourced, low bid subcontractors working for giant military industrial corporations, who can you trust?

Comment by Ballenger on "Dvorak Uncensored" blog

I used to work on the 737 line at the Boeing plant in Renton, Washington [JIN: where the fuselage sections from Wichita, KS, are put together], and this doesn’t surprise me. Shoddy work is fairly common. Sadly, Boeing is still the best of the bunch. While working on Airbus planes I’ve found structural and casting defects hidden with body filler (Bondo-type material for you car guys). I fly if I have to, but I prefer to take the train.

Comment by Mike on "Dvorak Uncensored" blog

REACTION at McLEAN HIGH SCHOOL, VIRGINIA

Jerry '60: I was a kid living in Europe when de Havilland made its own mistakes with the fuselage skin of the Comet airplanes --- the world's first commercial jetliner. The cold war was closing in, and these airplanes kept falling out of the sky. It was pretty scary, which is why I remembered it. The other famous metal fatigue incident in history involved Liberty cargo shops hastily made to supply the troops abroad during WW II. They fell apart in mid-ocean. The Comet's cracks started at the corner of the windows. The Liberty ship's cracks started at the corner of a cargo hold. Moral: always round off your corners. Anyway, now you know why they always X-ray planes. They all have cracks; someone decides when they should stop flying. Feeling better now?

Pam '59: If you are feeling better, why not relax and watch "No Highway in the Sky", a prescient 1951 movie about planes that crash from metal fatigue. Duke '60: Better yet, read the book the movie was taken from: No Highway (1948) by Nevil Shute [Norway], the guy who wrote On the Beach.

Nancy '60: We wanted the Comet, it was the only jet and so much faster. I do remember the Comets being grounded. We were in Burma at the time getting ready to come home and instead of BOAC's Comet I think we came home either on TWA or Pan Am.

Frank '60: ... there was the Aloha Airlines jet that had a large section of the top of its fuselage blown apart but with only the stewardess lost (wear your seatbelt) ... the cause was metal fatigue due to so many inter-island take-offs and landings. One passenger had noticed an anomalous bulge in the side of the plane before the catastrophic decompression. Maybe you remember the details.

Duke '60: ...and let's not forget the catastrophic fuselage failure at 24, 000 feet near Maui in 1988 of a 737-200 (N73711) flown by Aloha Airlines where a skin crease cracked along lap joints under the forces of pressurization and became a full-blown rupture. A senior flight attendant was sucked out through the hole and vanished; 65 of the 89 passengers were injured -- 8 seriously. [JIN: how nice to know the 737s are being built so much more carefully today . . . ]

click

to enlarge

Aircraft

assembly hall, from the Y2000 Annual Report of Ducommun Inc., a

venerable California company. It is painful to see this

happening to them, or to Boeing either, for that matter.

Ducommun was accused of using routers to cut the panels of fuselage skin when CNC (Computer-Numeric-Controlled) machinery was specified. Numerous parts were off-spec. Management retaliated against workers and Q/C personnel who tried to set things right. The most interesting point is that the required written certifications of independent FAA inspectors for numerous parts were never given, so that, legally, the planes were never certified airworthy to fly. Hats off to all the decent people who tried to do the right thing. Sorry they hurt you. We were a great nation once.

No longer.

Ducommun was accused of using routers to cut the panels of fuselage skin when CNC (Computer-Numeric-Controlled) machinery was specified. Numerous parts were off-spec. Management retaliated against workers and Q/C personnel who tried to set things right. The most interesting point is that the required written certifications of independent FAA inspectors for numerous parts were never given, so that, legally, the planes were never certified airworthy to fly. Hats off to all the decent people who tried to do the right thing. Sorry they hurt you. We were a great nation once.

No longer.