"Tina's

Tiny Table Top"

A Butcher Block from the

Ridgway Refrigerator Company,

Philadelphia ca. 1900

--=o=--

J. I. Nelson, Ph.D. 2009

bottom & links

In

1970 I stumbled across an abandoned butcher block lying on its

side in a tumble-down shed. Now,

40

years later, I need a household without 400 lb pieces of furniture --

and a new friend for my butcher block. This is the story of

the

butcher block's passage through its life, and through mine,

to a new

home.

Part I; The Butcher Block's Life - YOU ARE HERE

Part II. The Butcher Block and Me

SIZE & WEIGHT

31"

x 35" x 33" high,

400 lbs

The

block itself is 31" square.

The

2" thick knife holders on either side bring the block's

dimensions to 31" x 35".

The

bolts are longer still:, so overall

clearance is 31" x 37"

The

maple block is about 15 1/2" high (originally

thickness16"?)

Legs

are 17 1/2" long, 20 1/2" overall.

15.5

+ 17.5 = 33" high.

BOLTS:

The original block had

four 5/8" through-rods, threaded 5/8-11

(NC,

standard National Coarse threading). Adding the knife holders required

new, longer rods (again, 5/8-11). All butcher blocks

this size

that I have seen have through-rods, but on some blocks, nut and washer

are in a recessed hole, and the hole is covered with a wooden

plug. This block originally had cup-shaped metal bolt covers

over

the nuts.

BOLTS:

The original block had

four 5/8" through-rods, threaded 5/8-11

(NC,

standard National Coarse threading). Adding the knife holders required

new, longer rods (again, 5/8-11). All butcher blocks

this size

that I have seen have through-rods, but on some blocks, nut and washer

are in a recessed hole, and the hole is covered with a wooden

plug. This block originally had cup-shaped metal bolt covers

over

the nuts.

Weight

385 lbs top + 15 lbs legs = 400 lbs.

BOARDS &

BUTCHER BLOCKS

98

pieces of 7/4 maple board make up the butcher block.

The

boards of "7/4 maple" stock were all cut to 16" lengths.

The boards' widths vary, down to square (1 3/4" x 1 3/4").

The

boards are stacked ends-up to form a true butcher block surface of

end-grain wood. Maple is a diffuse-porous wood like cherry

and

can be used this way. Ring-porous woods like oak -- the ones

with obvious, regular tree rings -- would split.

Long

7/4 boards (12 feet, not 16 inches) from this era were used to make

maple counter tops. Older counters have boards as wide as 12

inches. Gluing (joining) boards edge-to-edge to reach the desired

counter top width is sometimes called "jointed

flat-grain construction".

The counter top exposes boards of varying widths, some

well-figured -- with a nice "grain" pattern, people say. But

"grain" is the wood's small fibers ("That water raised the grain -- the

board feels fuzzy." "The plane caught, it lifted the grain and made a

small pock mark."). Pretty patterns that tree rings trace across

a board's surface are the wood's "figure."

Long

7/4 boards (12 feet, not 16 inches) from this era were used to make

maple counter tops. Older counters have boards as wide as 12

inches. Gluing (joining) boards edge-to-edge to reach the desired

counter top width is sometimes called "jointed

flat-grain construction".

The counter top exposes boards of varying widths, some

well-figured -- with a nice "grain" pattern, people say. But

"grain" is the wood's small fibers ("That water raised the grain -- the

board feels fuzzy." "The plane caught, it lifted the grain and made a

small pock mark."). Pretty patterns that tree rings trace across

a board's surface are the wood's "figure."

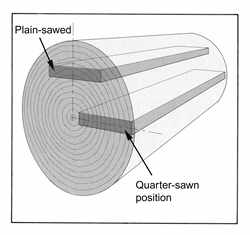

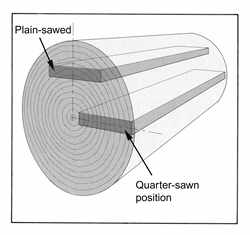

From a

woodworker or sawmill's point of view, 12" wide maple boards

can

only be obtained by "plainsawing" across the entire tree. Boards which

are narrower and which do not pass through the center of the tree are

all called "plainsawed". Particularly for

ring-porous woods like oak, the figuring of plain-sawed boards is

stronger, as the plane of the board intersects the rings of the tree,

making conic sections and other patterns. Although

plain-sawed

boards are the plentiful, cheap ones, plain-sawed boards need

more careful drying and aging, as they are most likely to

warp.

Most

shrinkage in wood occurs along the annual rings, and these are not

aligned with either the wide surface or the narrow edge of a

plain-sawed board .

. . and, they may slant in opposite directions on opposite

edges of the board, because the tree was small. This produces

cupping when everything is symmetrical, and horrible curvature or even twist when

it isn't.

Even

today, 1

3/4" remains a standard maple counter top thickness.

Counters

thicker than 7/4 are made by turning boards on  edge

and gluing the plain-sawed faces. For a 2 1/4" thick

industrial

counter top, for example, all the 7/4 maple boards are ripped

and jointed to that 2

1/4" width, then glued. The counter top with this "edge-grain

construction"

exposes homogeneous-width strips with little or

no

figure, but greater surface hardness.

edge

and gluing the plain-sawed faces. For a 2 1/4" thick

industrial

counter top, for example, all the 7/4 maple boards are ripped

and jointed to that 2

1/4" width, then glued. The counter top with this "edge-grain

construction"

exposes homogeneous-width strips with little or

no

figure, but greater surface hardness.

Edge-grain

construction is a compromise between end-grain construction

(the

hardest) and jointed flat-grain construction (the softest but sometimes

best-patterned). Only end-grain construction should be called

a

"butcher-block counter top" -- "edge-grain

construction" is an also-ran, and "jointed

flat-grain construction" has nothing to do with what you see in any real butcher block.

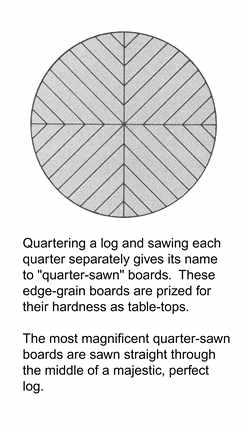

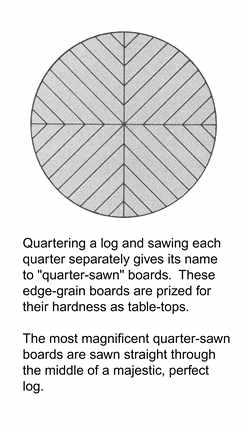

The

most sought-after

boards from any tree:

Return to that one plain-sawed cut through the center of the tree.

Except for the very middle, most of that board is edge-grain;

most of it is a stack of perfect annual rings. Cutting this

down

the center to get rid of problems (sap pockets, rot), the two

boards from the left and from the right side of the tree are

called "quarter-sawn". Normally logs are quartered to make

quarter-saw boards -- see illustration.

Quarter-sawn

lumber is the most

treasured

for table tops, whether the finest dining room furniture or workshop

counters, whether hard or softwood. It combines the hardness

of

edge grain with the beauty of boards having--like plain-sawn boards--

greater, varying width and more aesthetic figure. The boards

are normally not very wide. In the

rare,

perfect tree, "cheap" plain-sawing yields a magnificent, wide,

edge-grain

board from the log's one center-cut only. People paw through the stock at lumber mills hoping to find one.

Edge-grain

counter top construction is not only a compromise in

hardness between the jointed flat-grain (plain-saw) approach and

end-grain, it is also what you do in a world without thick, premium

quarter-sawn boards because that world has lost its

large-caliber, first-growth, native

hardwood trees.

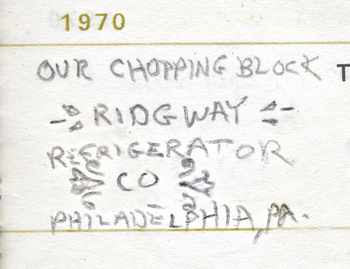

THE RIDGWAY

REFRIGERATOR COMPANY

The

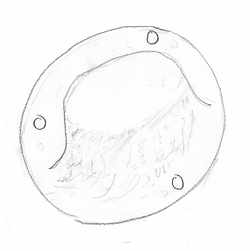

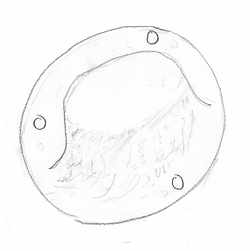

butcher block had

a stamp burned into its side and nearly obliterated by weathering.

There was nothing to photograph. I figured out what it said

and

sketched the stamp in my pocket reminder book for that day in July,

1970: As we shall see, this stamp fixes 1907 as the block's

oldest possible

date

of birth.

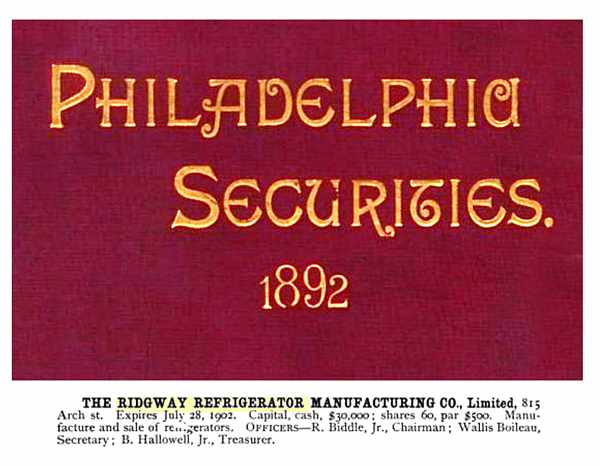

The

Ridgway Refrigerator was active in the 1890s.

The

text above reads:

The

Ridgway Refrigerator

Manufacturing Co. Ltd.

formerly The Ridgway Patent Refrigerator Company Limited

815 Arch St.

Stock issue expires 28 July 1902.

Capital, cash, $30,000.

Shares 60, par $500.

Manufacture and sale of refrigerators.

Officers: R. Biddle, Jr., Chairman

Wallis Boileau, Secretary

B. Hallowell, Jr., Treasurer

Besides

this entry in a leather-bound listing of "Philadelphia

Securities

1892", the company appears in a 1907-1909 company listing has having

shortened its name ("charter") to "Ridgway Refrigerator Company," the

name stamped on this butcher block. This fixes the oldest

possible date of the block at 1907.

The

oldest

date I find for the company itself is 1886, the year two

men

-- presumably employees -- assigned their patent rights to

the

company. The Annual Report of the Commissioner of Patents by

the United States Patent Office for 1886 reports that William J.

Taylor and H. J. Chester are assignors of their

patent

rights to the Ridgway Refrigerator Manufacturing Company Ltd.

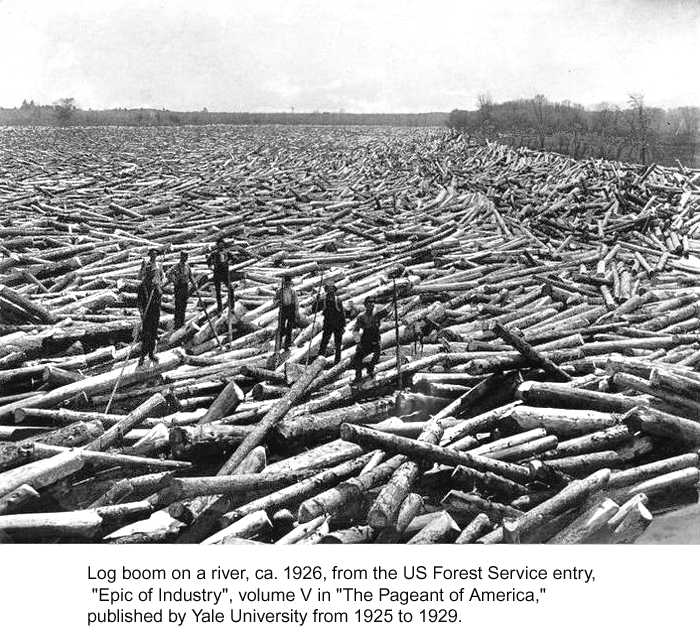

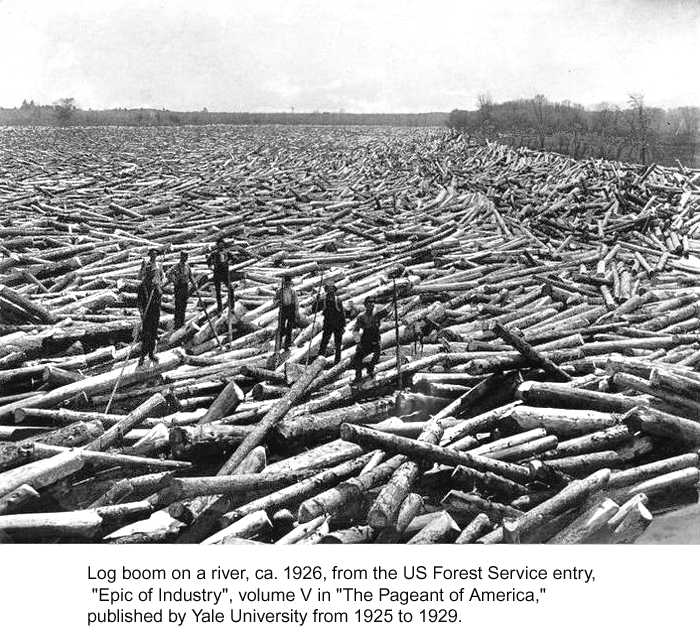

LUMBER BARONS and MILLIONAIRES

During

the lumbering frenzy of the late 1800s, the log boom across the Susquehanna at

Williamsport held back the world's largest log pile. The boom

itself was made of logs chained together. If your logging

venture

was participating in that season's "river drive," you would

clear-cut the hills to which you could claim rights ("claim" is the

polite word), brand the logs like heads of cattle,

and drive

them through the Susquehanna Boom for a tariff . Your brand

of

logs had to be sorted into their own circular boom and taken down to

the holding pond of the mill you used for sawing (the "mill

pond"). Every step made (extracted) money, and people who

fought

their way towards a vertical monopoly made the most. The

1880s

were the opposite of the 1980s, when many industries

globalized

and "delaminated"; i.e. businesses became more specialized

and mutually cooperative, supported by computerized

business practices and a global, data-oriented networks for

connecting them.

As

America first industrialized, whoever

owned the Susquehanna Boom could charge levies on every log

that passed it. At the height of the lumber

industry in Lycoming County, 1861-1891, the mills produced

5.5

billion board feet of lumber. Williamsport became one of the most

prosperous cities in the United States, with more

millionaires

per capita than any other town. Men like James H.

Perkins,

Peter

Herdic, and Mahlon

Fisher became millionaires while many of the men who actually worked in

the river struggled to survive on the wages paid them by the lumber

barons. Some died of injuries. Williamsport is

worth

visiting today just to see the architectural landmarks left in the town

by Peter Herdic. To retain control of the Susquehanna Boom,

the

richest tollgate on land or water, Herdic proceeded to

bribe every

legislator in the state assembly.

In big

cities like Philadelphia, the flood of native hardwoods

created companies like the Ridgway

Refrigerator and Manufacturing Company and products like this butcher

block.

(Further north, oak fed office and home furniture

industries.)

In the

1860s the state of Pennsylvania led the nation in lumber

production. By 1900, the state it had dropped to fourth

place. Clear-cutting insured that hillsides would not come

back. Most

hardwood produced today is low-grade from small-diameter trees and

winds up as a shipping pallet.

The

plundering of virgin native-growth (first-growth) forests by members of

his

own family disturbed James Pinchot, who left Milford, PA, to return a

millionaire from his success as a wallpaper dealer in New York City.

He endowed the Yale

School of Forestry

in 1900 -- the first graduate forestry program in the country -- too

late for his son Gifford Pinchot (Yale, '89). From Grey Towers,

the family estate in Milford overlooking the Delaware

River, James

sent Gifford to a postgraduate year at the French National

Forestry School. As the nation's first professional forester, James'

son would make amends.

When Federal

supervision of the nation's forests was transferred to the Department

of Agriculture in 1905, Gifford Pinchot (1865-1946) was put

in

charge. He served from 1905-1910 and later won two

terms as

governor of the

state of Pennsylvania. That "Bureau of Forestry"

became the

US

Forest Service.

PROTECTING OURSELVES FROM

THE PROTECTORS

John

Muir

(1838 – 24 December 1914) joined forces with Gifford Pinchot long

enough (1896-1897) to launch the nation's conservation movement.

Pinchot

was a utilitarian untouched by Muir's respect for the spiritual value

of beauty.. For Pinchot, the world was new, and Man

would

control it. Man controlled nature; and nature would support

man

as he spread and multiplied. For Pinchot, forests were tree

farms

-- cut one down, plant another. If planted trees made softer

wood, that was an engineering problem. If native growth trees

made boards with swirling figures, that only made them harder to mill

into furniture. If swirling figures looked different from

plain

grain, that was only beauty and of no intrinsic value to Man's

Progress. Theodore Roosevelt came to Gifford

Pinchot's wedding. His wife

added

an outside dining room to their mansion so that more guests could be

entertained as the couple sought the Senate, the House and the state

governorship. Buoyant bowls floated the food from guest to guest at

"The Finger Bowl" table (photo, right). The family

mansion is open to

the public today.

Pinchot

was a utilitarian untouched by Muir's respect for the spiritual value

of beauty.. For Pinchot, the world was new, and Man

would

control it. Man controlled nature; and nature would support

man

as he spread and multiplied. For Pinchot, forests were tree

farms

-- cut one down, plant another. If planted trees made softer

wood, that was an engineering problem. If native growth trees

made boards with swirling figures, that only made them harder to mill

into furniture. If swirling figures looked different from

plain

grain, that was only beauty and of no intrinsic value to Man's

Progress. Theodore Roosevelt came to Gifford

Pinchot's wedding. His wife

added

an outside dining room to their mansion so that more guests could be

entertained as the couple sought the Senate, the House and the state

governorship. Buoyant bowls floated the food from guest to guest at

"The Finger Bowl" table (photo, right). The family

mansion is open to

the public today.

For Pinchot's US Forest Service, "conserve"

meant exploiting resources in (hopefully) renewable ways.

What happened? In the Dept. of Agriculture, farmers produce

soybeans, corn, wheat, with subsidies

Congress cannot stop.

Cattlemen have access to public grazing lands; and

lumbermen have access to forests.

The

butcher block gave us the US Forest Service, but only

through

John Muir did we get protection from the protectors.

As

co-founder and first president of the Sierra Club, Muir wielded

national power and walked with Presidents. His friendship

with

Gifford Pinchot ended in 1897 over a sheep grazing dispute,

and

sharpened with the campaign to dam Hetch Hetchy Valley,

which violated Yosemite National Park, CA. The ultimate

approval

of the dam was heartbreaking to Muir, who died a year after losing

this, his

last great fight. A national park had been exploited, an

entire valley destroyed

State power? The

violation of a national park to build a dam led ultimately to

the

formation of the National Park Service (1917) to protect all

national parks. Stephen

Tyng Mather

(July 4, 1867 - January 22, 1930) was first director (1917)

of the helpless,

new National Park Service in the Dept of the Interior (the

Forest Service remains in the Dept. of Agriculture).

A

millionaire (Thorkildsen-Mather Borax Company),

manic-depressive, and tireless promoter of rail and road access to the

parks, Mather understood that the parks' product was beauty, not lumber

or dammed water. The Parks became overrun with tourists

arriving

on Mather's roads, but that success brought political power, and the goal of

cherishing beauty was established.

Robert Underwood Johnson,

editor of Century

Magazine

which published many of John Muir's articles, wrote that "the world

will ... remember the voice of one crying in the

wilderness and bless the name of John Muir. . . . He sung the glory of

nature like another Psalmist, and, as a true artist, was unashamed of

his emotions. ... His countrymen owe him gratitude as the

pioneer of our system of national parks. . . . Muir’s writings and

enthusiasm were the chief forces that inspired the movement. All the

other torches were lighted from his."

The

plunder and pillage of the Eastern hardwood forests got us this butcher

block and at least some

professional forest management, but it took the stunning beauty of the

West to get us a Park Service for preserving our best

lands, not just conserving

their resources by exploiting them in what we are told are renewable

ways. ad

CUSTODIANSHIP

This

country will never again stack 400 lbs of rock

maple together to sell butcher blocks to the

world --

never mind that industrialized pork production caused this

butcher

block to be abandoned, and caused the market for all of them to disappear -- to disappear from family

corn-and-hog

farms, from neighborhood butcher shops (see,

for

example, the documentary film Food,

Inc,

available from amazon).

This

butcher block was older than I was when I got it, and it still

is.

Now I must pass it on. I have lavished an

irrational

amount of

care on it, despite international moves to Europe and Australia.

I wanted this butcher block to be there when I wasn't.

So

if doing something that does not benefit you, and you first, is

irrational, then I stand guilty as accused. I hope it stays

with

the next owner

for generations.

HAIL, SALE AND FAREWELL: We

got a quick answer to our classified ad. The First Responders

didn't seem to think me crazy to ask if the block would have a good

home. There were several

romantic

window shoppers with no idea of what shipping a 400 lb object entailed,

let alone just lifting it.

"This

weighs 400 lbs.

Are you sure you can handle it?" I asked one First

Responder, a

Little Girl Voice (Tina) on the other end of a long-distance call.

"We

run a family business, Atlantic

Structure Movers.

We move

houses."

I

put down the phone.

Most

people walk away, tear down, build new. A

structure-moving company caters to people who have something of

historic value, who respect the cultural significance of

things,

who understand that continuity of place supports a family across

generations. That is the connection. My butcher

block will

have a good home. I hope they keep it forever.

Part I; The Butcher Block's Life

Part II. The Butcher Block and Me - YOU ARE HERE

ACQUISITION, 1970

We

conclude with the butcher block's acquisition, and its care and

assembly, ending with contact information for the

previous

(original?) owners in

Delaware.

I

got this butcher

block on the Fischer family farm in Lewes, Delaware, in the

summer

1970. Robin and I (Swarthmore College 1967 and 1965

respectively)

were visiting schoolmate Donna Fischer and her first husband Carl F

Goodwin (both Swarthmore class of 1968) on her parents' farm.

Donna

said Let's pile into the car and cruise the dairy queen as she did in

high school. I thought, This is one of those mythical family

farms and I want to see it, so after ice cream all around, we set out

walking across a vast cornfield with a shed at the distant edge.

The cornfield's rows went around the shed -- no yard, no path,

no

visitors, the most totally ignored structure ever built.

The butcher block was lying alone inside. The

shed

had been a slaughter house for the farm. Years later in the midst of restoring it, I

would

find blood between the butchering block's boards. Being on its

side,

all four leg bottoms were dry and perfect. The butcher block

wasn't in the mud exactly, but on soggy floorboards. Perhaps

the

shed's flooring had collapsed and that's how the block tipped over in

the first place. Slow, silent death, unable to crawl to the

phone for help.

I

had to have it. I begged. Donna Fischer asked her

parents if it was OK. They said they weren't raising

hogs

anymore, so if you can figure out how to move it, it's yours.

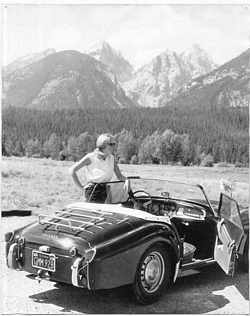

I

had courted Robin with a real sports car, but now I had a VW bug to

prove I was not only married, but sensible. We borrowed tools

and

unbolted the front seat entirely. My new passenger took up

the

entire passenger side of the car. I didn't want to leave

either

the butcher block or the car seat behind, plus I had a wife.

Robin rode home to Long Island in the back of a VW beetle, with the seat on her lap,

begging

to be let out. The VW bug listed badly to the side.

I could

turn right

at any speed, like being back in my sports car again, but on long

interstate ramps to the left I wondered if we'd hear the running board

scraping on the concrete roadway before the whole package just rolled

down the embankment. We stored the butcher block in a

friend's

basement while I finished my Ph.D. on Long Island and did postdocs in

Chicago and then Australia. The Fulbright to Australia spun

out

into 5 years. On trips home, I went down into the

basement, opened the can of linseed oil, and gave the butcher block

another coat to preserve the wood.

I

had to have it. I begged. Donna Fischer asked her

parents if it was OK. They said they weren't raising

hogs

anymore, so if you can figure out how to move it, it's yours.

I

had courted Robin with a real sports car, but now I had a VW bug to

prove I was not only married, but sensible. We borrowed tools

and

unbolted the front seat entirely. My new passenger took up

the

entire passenger side of the car. I didn't want to leave

either

the butcher block or the car seat behind, plus I had a wife.

Robin rode home to Long Island in the back of a VW beetle, with the seat on her lap,

begging

to be let out. The VW bug listed badly to the side.

I could

turn right

at any speed, like being back in my sports car again, but on long

interstate ramps to the left I wondered if we'd hear the running board

scraping on the concrete roadway before the whole package just rolled

down the embankment. We stored the butcher block in a

friend's

basement while I finished my Ph.D. on Long Island and did postdocs in

Chicago and then Australia. The Fulbright to Australia spun

out

into 5 years. On trips home, I went down into the

basement, opened the can of linseed oil, and gave the butcher block

another coat to preserve the wood.

We

returned from Australia in 1978 to a job at the State

University of New

York at Stony Brook, Dept. of Neurobiology, and retrieved the

butcher block.

There had been particulate matter in the basement (smoky

furnace?). The linseed oil had remained

receptive a

long time because there was little air movement and no ultraviolet

radiation from the sun to dry it. Instead of the rich, deep

wood

color I imagined after 8 years of TLC, the block was, in

fact,

almost black and would have to be refinished. After work on

the

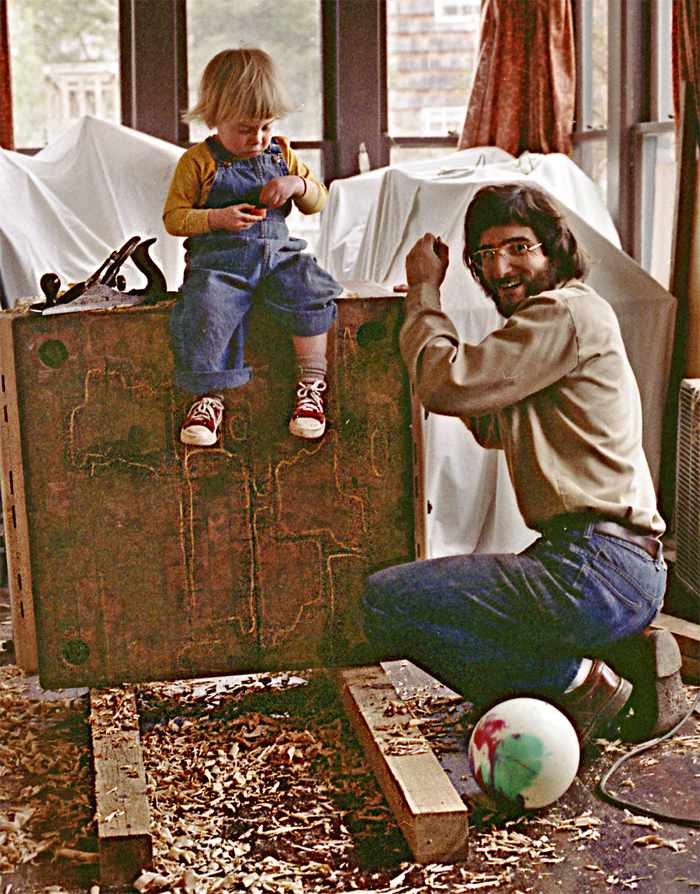

house itself, I turned to the butcher block in early 1980. My

son

was at the age when everything is fascinating and Daddy seems normal.

RESTORATION, 1980

1.

Down to the wood.

There

was no finish to save. I went down to the wood with

hand planes on

all four sides, removing the discoloration (photo above; the

author and

Lorrin, April, 1980).

2.

Soft on one side.

One

side

(one with bolt heads) had been the side on the

ground

(on the

old shed's disintegrating floor boards). The wood is still

stained with iron today (blueish black) from the bolt covers which

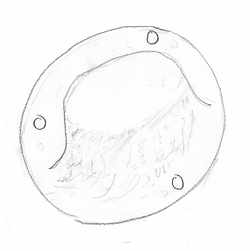

rusted through (sketch, right; stains below, running out from under the new bracing boards). I abandoned

the idea of bolt

covers because I wanted to use washes as large as the bolt covers

themselves. Then I would be able to apply

tremendous

pressure to stabilize the block once I got the alignment right.

3.

Knife holder "bookends" with new bolts.

Even

with large washers, the softened wood in the

first layer of boards on one side might get crushed. I had

seen

butcher blocks

--

mostly smaller ones intended for use in retail butcher shops -- that

had knife holders on opposite ends, so I added rock maple knife holders

to use as "clamp faces" under the bolts. This

brought to

wood to 31"

+

(2 x 2")) = 35", so all the pre-threaded, 36" long rods in all the

hardware stores of America were useless. I needed

37".

I know this never happens to you, but in my life there are always

projects like this. I

ordered 5/8 plain rod from a steel dealer, cut generous 37" lengths,

and threaded all the ends with the same 5/8-11NC thread -- better than

the hardware store, black rods with threading just at the ends, just

like before. Just do a couple rods, wait for your hands to

heal,

do some more. I had had a college-level course in machine

shop

practice, but my basement was no machine shop.

4. Sand

top, apply finish.

4. Sand

top, apply finish.

I

was able to scrape and sand the top without losing the contour because

the dirty linseed oil was soft and the endgrain was hard. I

sanded until there was no scratch anywhere from sandpaper, and the old

cleaver marks from slicing and slaughtering emerged. The rounding

of every edge began to look optically perfect in reflected light. The

refinishing itself --

however regrettable -- became invisible.

Since

I wasn't

going to use the block for cutting wet food, I gave the top and the

sides the same coat of varnish. The top got almost nothing --

rubbed on with a rag, not painted with a brush. The top had

been

virtually pre-polished by a progression of finer grits to a

shiny

surface even unfinished -- it didn't need much.

To use the block for food, rub the surface with tung oil or Behlen

salad bowl finish in order

to add a coat with some

penetration.

5.

Be the first in 100 years to re-glue.

To

this day, the block falls apart into a dozen and a half big hunks and

several smaller pieces. It is not [re-]glued. The

breaks are mostly along the old glue

lines, which have failed

from age and dampness in the slaughter shed, but some splits are right

through the boards.

click

either image to enlarge

Men worked at each corner, leaving the worn surface saddle-shaped (left).

Nails hammered into the block to hold a rag made the chips at the edge.

The surface still shows the marks of old cleaver blows (right).

STEWING OVER

GLUING

click to enlarge

click to enlarge

Chalk

lines trace the

chunks into which the butcher block falls apart.

One or two breaks cross a (broken) board.

The pencil numbers on the 98 boards that make the block are repeated in

red on the photo.

The legs are keyed A-B-C-D going counterclockwise.

Hammer marks on the bottom commemorate my efforts to get the top even.

GLUING

GLUING:

I was chicken to glue the block back together. My

excuse

was that I might move, and yes, the whole thing did go to

Germany with

us, but we traveled with His and Hers SeaLand containers and didn't

need to take any furniture apart. The real reason for not

re-gluing was that I

didn't know if I'd ever get the top perfect. I might have to

accept a

corner on an individual piece (or two) that was not lining up because

it had become misaligned during use and that corner got rounded

off. But I got the top perfect. Now that we know all pieces

can slide into

alignment -- I say, Glue it.

Use only animal or "liquid hide glue," as a curator or

restorer of any piece of antique furniture would also do.

- Modern glues are stronger than the wood -- breakage is

guaranteed to destroy the object, not open a joint.

- Liquid

hide glue takes a long time to set, and you may need hours before you

can run your fingers (crossed!) across the top, know it is perfect, and

tighten those bolts.

- Liquid hide glue is slippery & gelatinous, while many modern glues are thixotropic (designed to be

sticky).

You need to slide the pieces.

EXPANSION/CONTRACTION

AS THE SEASONS ROLL: :

The wood "works". Even with air conditioning, the

block

expands in summer and contracts during the dry winter heating season.

If you don't tighten the bolts as winter sets in,

you may lose it.

If you forget to loosen a sixth-turn (15 mills) every once in

a

while in summer, the washers will crush their way into the knife

holders as the massive wood object expands. When

that happens, the

block

has changed shape -- permanently. During the next winter

contraction, it will be looser. If the block were glued, the

bolts wouldn't have to be tight enough to cause a "summer expansion

crush". Everything's OK so far, but

glued would be simpler in the end.

click to enlarge

PUTTING

THE LEGS ON

PUTTING

THE LEGS ON

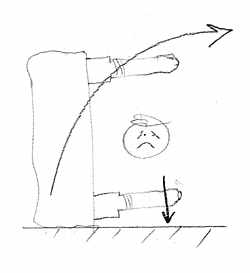

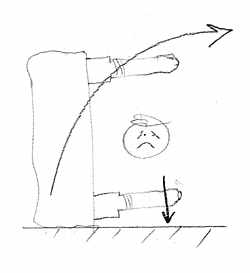

If

you just put the legs on and expect to tilt the block back up, then you

need guys prepared to lift 400 lbs of dead weight. And there

is

no hand purchase. This means your guys should

have canvas belts

(like piano movers) and know how to use them.

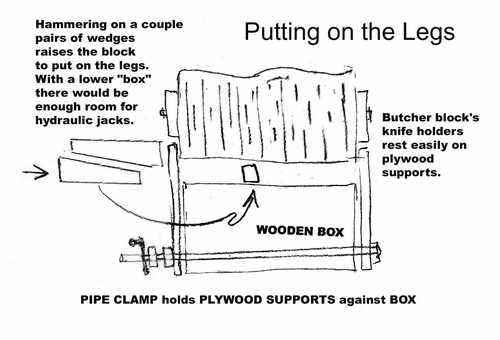

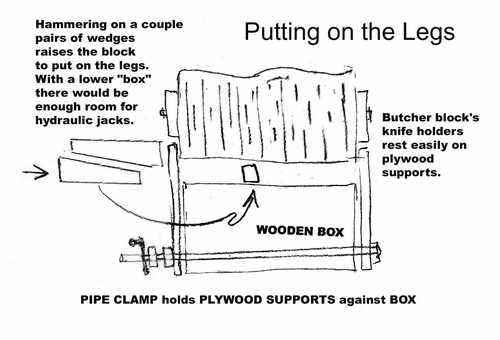

I

made a support that went under the knife holders, and had my helpers in

Germany put the block up on the supports. I raised the block

3

more inches with two

pairs of wedges to get the legs into their holes, then lowered the

block

to drive the legs in. After adjusting the legs' fox tail

wedges

for a tight fit for each leg (see below), I took the supports away.

You could bring this technology from the age of the Pharaohs

to

the Industrial Age by creating a support with enough free space for a

couple hydraulic (car) jacks -- see diagram.

4x4

stock is turned down to a 2" diameter "dowel" to fix each leg

in

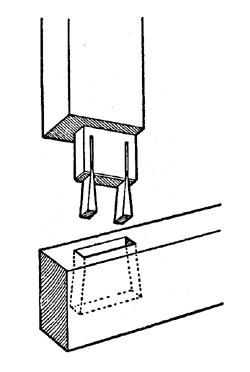

place. The

3" long

dowels slides into 4" long holes. As they hit the hole's

bottom,

foxtail wedges are forced into the dowel, locking the leg tight.

The length dimensions are very critical. The legs

are keyed

to their holes and the wedges can't trade legs. Twist each leg in

and out of its hole and learn to feel where the foxtail wedge hits

bottom. A wooden carpenter's clamp (wooden handscrew clamp) makes

a good wrench to turn a leg that sticks. You shouldn't

be

satisfied with anything less than a perfectly tight leg -- no wobble --

so put half a 3x5 file card folded into the bottom of the hole to push

harder on the wedge and lock the leg a little tighter when you are done

and drive all the legs home later. Move up

gradually. If you overdo it,

the leg

will lock before it is seated and you may not be able to get it out.

Rub the dowels down with an old candle if you can't find

beeswax.

Believe me, making a 2" diameter dowel slippery so you can

position it is not a problem. It will lock up solid as steel

when you get the wedge (& file-card filler) right.

The

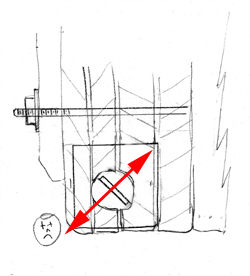

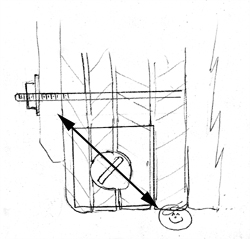

foxtail wedge runs obliquely inside the leg, corner to corner.

With the tops of the legs aligned with the corner of the butcher

block itself, we find a bad and a good orientation for the wedge.

The bad

orientation splits the corner out of the block; the good orientation

puts pressure against the tensile strength of the steel bolt

on

one side, and against a long stack of boards on the other side.

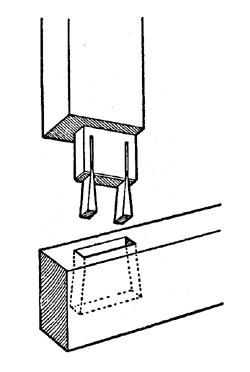

Blind (left) and exposed or "through" (

right)

foxtail-wedged mortise

& tenon joints.

The

foxtail wedged joint is traditional in furniture joinery. A

century ago, it was often "blind" (hidden) as the leg joints of the

butcher

block are. In modern times, through-joints are more

common; the

fox-tailed mortise and tenon joint is considered decorative.

(In a mortise and tenon joint, the tenon is the "tongue" that

sticks into or through the other piece being joined.)

THE OWNERS BEFORE

1970

The

block was on the family farm of Donna Elaine Fischer (Swarthmore

College, Class of 1968)

Alumni

Office address in 2009:

10

Lighthouse Way

Lewes, Delaware 19958

tel (302) 645-7922

Signed

up for 40th reunion in 2008.

Sometimes

goes by Donna Fischer-Scrivo, taking the name of her 2nd

husband.

The

Fishers,

a Quaker family, have lived in Lewes at

least since the Revolutionary War.

If we can get in touch with Donna, we could learn if she is part of

that family but uses a variant on the spelling of "Fisher", or

whether the names are just a coincidence. All of us (Donna

and her first husband, Robin & I) certainly

met

at a Quaker-founded institution, Swarthmore College. In any

event, the length of time her family owned the farm property would be

helpful for dating this butcher block. The date her

father or

grandfather launched into corn and hog farming points to

the date a butcher block became needed and might have been

acquired. As noted above, this butcher block

is not older than 1907,

based

on the variant of the company name once stamped on it.

--end

FAN LETTER (thank you!)

Date: Mon, 4 Apr 2011

Subject: RE: butcher block story

From: LM

To: jerry-va@speakeasy.net

RE: http://www.nerdylorrin.net/jerry/r+j/MyButcherBlk/ButcherBlk.html

I just had to thank you for your wonderful write up on your old butcher

block. I fell in love with one myself, back in my early 20's, and

saved it from an old home in Corktown outside of downtown

Detroit. I'm still amazed that I managed to get it out of the

1800's house it was in; however, we broke the dowels on two legs in the

process. It sat uncared for at an old boyfriend's house for

years, without oil, laying on its side under a staircase.

Fastforward to present day- I managed to get it to my current house,

legs still useless. I remade the dowels, and got into a heated

debate with every available strong man on the best way to get them on

and get the block upright. A quick google search produced your

webpage, and, with a little luck and ingenuity, we got the block

standing again last night. I attached two pics of the massive

thing, just because I'm excited to share.

Thank you again for the wonderful read on the restoration and history!

--end

top of this page ("A Butcher Block from Ridgway Refrigerator Co.")

Part I; The Butcher Block's Life

Part II. The Butcher Block and Me

home for this Website (such as it is) UCAN RETURN w/BackButton

Suggestions for changes, fixes: jerry-VA at removethistext speakeasy dot net

Rev 4Nov09; 17Jun2016 text flow/ambiguities; fan mail; 5Feb2018 moved on server for flatter file structure

Rev 25Jun2018 Oh my, how can there still be so many typos? :-(

BOLTS:

The original block had

four 5/8" through-rods, threaded 5/8-11

(NC,

standard National Coarse threading). Adding the knife holders required

new, longer rods (again, 5/8-11). All butcher blocks

this size

that I have seen have through-rods, but on some blocks, nut and washer

are in a recessed hole, and the hole is covered with a wooden

plug. This block originally had cup-shaped metal bolt covers

over

the nuts.

BOLTS:

The original block had

four 5/8" through-rods, threaded 5/8-11

(NC,

standard National Coarse threading). Adding the knife holders required

new, longer rods (again, 5/8-11). All butcher blocks

this size

that I have seen have through-rods, but on some blocks, nut and washer

are in a recessed hole, and the hole is covered with a wooden

plug. This block originally had cup-shaped metal bolt covers

over

the nuts.  Long

7/4 boards (12 feet, not 16 inches) from this era were used to make

maple counter tops. Older counters have boards as wide as 12

inches. Gluing (joining) boards edge-to-edge to reach the desired

counter top width is sometimes called "jointed

flat-grain construction".

The counter top exposes boards of varying widths, some

well-figured -- with a nice "grain" pattern, people say. But

"grain" is the wood's small fibers ("That water raised the grain -- the

board feels fuzzy." "The plane caught, it lifted the grain and made a

small pock mark."). Pretty patterns that tree rings trace across

a board's surface are the wood's "figure."

Long

7/4 boards (12 feet, not 16 inches) from this era were used to make

maple counter tops. Older counters have boards as wide as 12

inches. Gluing (joining) boards edge-to-edge to reach the desired

counter top width is sometimes called "jointed

flat-grain construction".

The counter top exposes boards of varying widths, some

well-figured -- with a nice "grain" pattern, people say. But

"grain" is the wood's small fibers ("That water raised the grain -- the

board feels fuzzy." "The plane caught, it lifted the grain and made a

small pock mark."). Pretty patterns that tree rings trace across

a board's surface are the wood's "figure."  edge

and gluing the plain-sawed faces. For a 2 1/4" thick

industrial

counter top, for example, all the 7/4 maple boards are ripped

and jointed to that 2

1/4" width, then glued. The counter top with this "edge-grain

construction"

exposes homogeneous-width strips with little or

no

figure, but greater surface hardness.

edge

and gluing the plain-sawed faces. For a 2 1/4" thick

industrial

counter top, for example, all the 7/4 maple boards are ripped

and jointed to that 2

1/4" width, then glued. The counter top with this "edge-grain

construction"

exposes homogeneous-width strips with little or

no

figure, but greater surface hardness.

Pinchot

was a utilitarian untouched by Muir's respect for the spiritual value

of beauty.. For Pinchot, the world was new, and Man

would

control it. Man controlled nature; and nature would support

man

as he spread and multiplied. For Pinchot, forests were tree

farms

-- cut one down, plant another. If planted trees made softer

wood, that was an engineering problem. If native growth trees

made boards with swirling figures, that only made them harder to mill

into furniture. If swirling figures looked different from

plain

grain, that was only beauty and of no intrinsic value to Man's

Progress. Theodore Roosevelt came to Gifford

Pinchot's wedding. His wife

added

an outside dining room to their mansion so that more guests could be

entertained as the couple sought the Senate, the House and the state

governorship. Buoyant bowls floated the food from guest to guest at

"The Finger Bowl" table (photo, right). The family

mansion is open to

the public today.

Pinchot

was a utilitarian untouched by Muir's respect for the spiritual value

of beauty.. For Pinchot, the world was new, and Man

would

control it. Man controlled nature; and nature would support

man

as he spread and multiplied. For Pinchot, forests were tree

farms

-- cut one down, plant another. If planted trees made softer

wood, that was an engineering problem. If native growth trees

made boards with swirling figures, that only made them harder to mill

into furniture. If swirling figures looked different from

plain

grain, that was only beauty and of no intrinsic value to Man's

Progress. Theodore Roosevelt came to Gifford

Pinchot's wedding. His wife

added

an outside dining room to their mansion so that more guests could be

entertained as the couple sought the Senate, the House and the state

governorship. Buoyant bowls floated the food from guest to guest at

"The Finger Bowl" table (photo, right). The family

mansion is open to

the public today.

I

had to have it. I begged. Donna Fischer asked her

parents if it was OK. They said they weren't raising

hogs

anymore, so if you can figure out how to move it, it's yours.

I

had courted Robin with a real sports car, but now I had a VW bug to

prove I was not only married, but sensible. We borrowed tools

and

unbolted the front seat entirely. My new passenger took up

the

entire passenger side of the car. I didn't want to leave

either

the butcher block or the car seat behind, plus I had a wife.

Robin rode home to Long Island in the back of a VW beetle, with the seat on her lap,

begging

to be let out. The VW bug listed badly to the side.

I could

turn right

at any speed, like being back in my sports car again, but on long

interstate ramps to the left I wondered if we'd hear the running board

scraping on the concrete roadway before the whole package just rolled

down the embankment. We stored the butcher block in a

friend's

basement while I finished my Ph.D. on Long Island and did postdocs in

Chicago and then Australia. The Fulbright to Australia spun

out

into 5 years. On trips home, I went down into the

basement, opened the can of linseed oil, and gave the butcher block

another coat to preserve the wood.

I

had to have it. I begged. Donna Fischer asked her

parents if it was OK. They said they weren't raising

hogs

anymore, so if you can figure out how to move it, it's yours.

I

had courted Robin with a real sports car, but now I had a VW bug to

prove I was not only married, but sensible. We borrowed tools

and

unbolted the front seat entirely. My new passenger took up

the

entire passenger side of the car. I didn't want to leave

either

the butcher block or the car seat behind, plus I had a wife.

Robin rode home to Long Island in the back of a VW beetle, with the seat on her lap,

begging

to be let out. The VW bug listed badly to the side.

I could

turn right

at any speed, like being back in my sports car again, but on long

interstate ramps to the left I wondered if we'd hear the running board

scraping on the concrete roadway before the whole package just rolled

down the embankment. We stored the butcher block in a

friend's

basement while I finished my Ph.D. on Long Island and did postdocs in

Chicago and then Australia. The Fulbright to Australia spun

out

into 5 years. On trips home, I went down into the

basement, opened the can of linseed oil, and gave the butcher block

another coat to preserve the wood.

4. Sand

top, apply finish.

4. Sand

top, apply finish.  GLUING:

I was chicken to glue the block back together. My

excuse

was that I might move, and yes, the whole thing did go to

Germany with

us, but we traveled with His and Hers SeaLand containers and didn't

need to take any furniture apart. The real reason for not

re-gluing was that I

didn't know if I'd ever get the top perfect. I might have to

accept a

corner on an individual piece (or two) that was not lining up because

it had become misaligned during use and that corner got rounded

off. But I got the top perfect. Now that we know all pieces

can slide into

alignment -- I say, Glue it.

GLUING:

I was chicken to glue the block back together. My

excuse

was that I might move, and yes, the whole thing did go to

Germany with

us, but we traveled with His and Hers SeaLand containers and didn't

need to take any furniture apart. The real reason for not

re-gluing was that I

didn't know if I'd ever get the top perfect. I might have to

accept a

corner on an individual piece (or two) that was not lining up because

it had become misaligned during use and that corner got rounded

off. But I got the top perfect. Now that we know all pieces

can slide into

alignment -- I say, Glue it.

I

made a support that went under the knife holders, and had my helpers in

Germany put the block up on the supports. I raised the block

3

more inches with two

pairs of wedges to get the legs into their holes, then lowered the

block

to drive the legs in. After adjusting the legs' fox tail

wedges

for a tight fit for each leg (see below), I took the supports away.

I

made a support that went under the knife holders, and had my helpers in

Germany put the block up on the supports. I raised the block

3

more inches with two

pairs of wedges to get the legs into their holes, then lowered the

block

to drive the legs in. After adjusting the legs' fox tail

wedges

for a tight fit for each leg (see below), I took the supports away.